You have no items in your shopping cart.

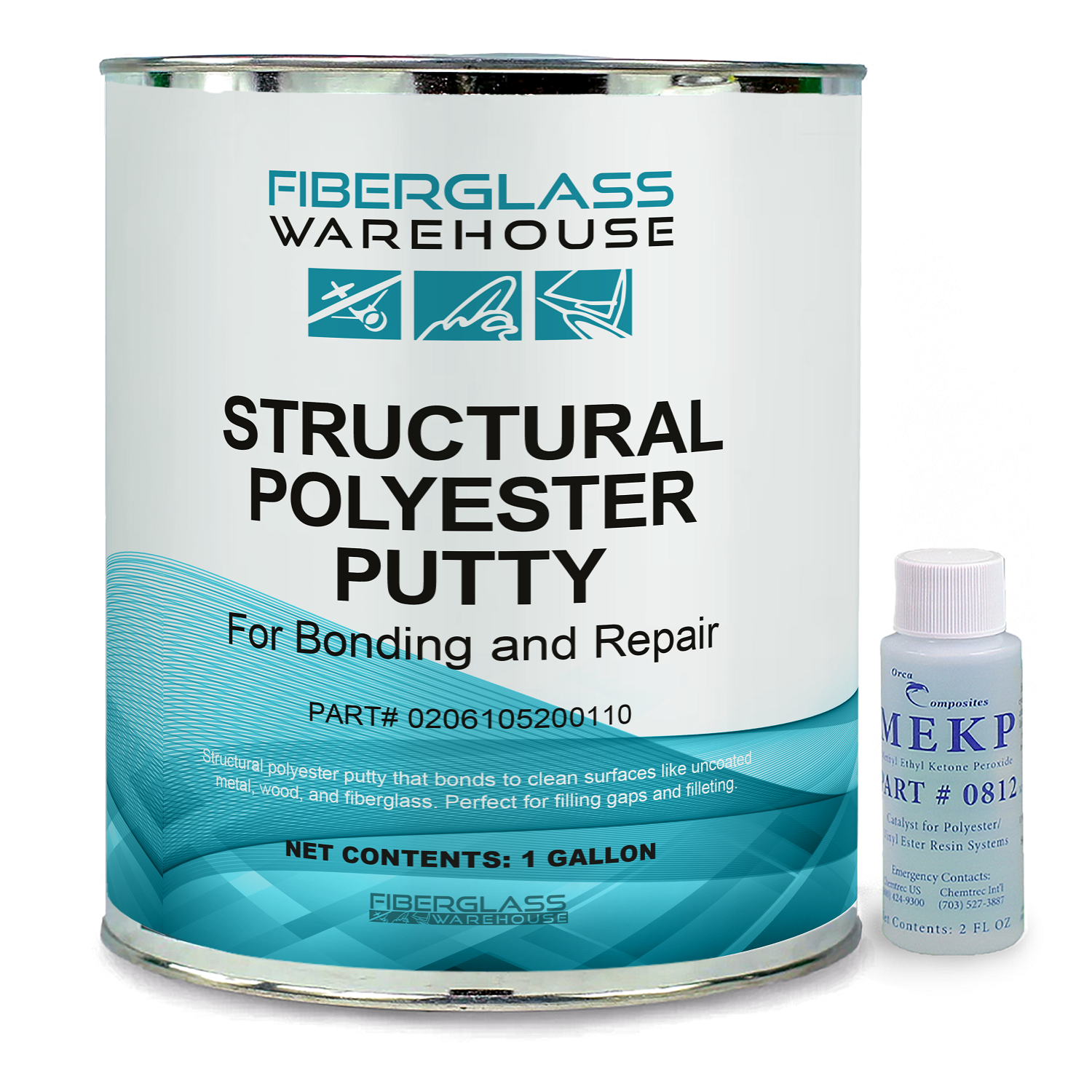

Structural Bonding Putty Details:

Fiberglass Warehouse Structural Polyester Bonding Putty is your go to for bonding and repair. This medium weight, two-component polyester putty is ideal for boat building, automotive and general-purpose composite projects. This putty includes premium grade polyester resin with added glass fibers that goes on smooth without sagging or shrinking. It sets up fast and creates a waterproof finish that is ready for sanding or gel coating.

Structural Bonding Putty is easy to apply and is a fast-acting formula that achieves great results with effortless prep and clean-up. It is optimal to use in 70-95°F with low humidity. From bonding, to filleting, to filling gaps and cracks, to radius forming, Fiberglass Warehouse Structural Polyester Putty has you covered.

Uses for Structural Bonding Putty:

-Filling gaps, cracks and holes in areas that do not experience significant flex or expansion

-Bonding fiberglass, uncoated metal, core material and wood surfaces. Great for critical applications such as hull to deck, stringers to hull, bonding bulkheads, plus more.

-Filleting

-Radius Forming

Features of Structural Bonding Putty:

-Specifically formulated for structural bonding that makes critical repairs and constructions worry-free.

-Waterproof finish ensures your repairs stand the test of both time and elements.

-Easy application

-Durable bond or repair

-High tensile and flexural strength

Needed Supplies:

Structural Polyester Bonding Putty

MEKP

Spreader or putty knife

Stir Sticks

Safety Protection including gloves, mask and eye goggles

Application:

-Work area and resin should be between 70°F and 85°F for best results.

-Make sure the work area is well ventilated and wear proper safety clothing including gloves and a face mask.

-Prep surface by sanding and then cleaning with acetone or other solvent.

-Measure out the putty in measuring cup

-Add MEKP based on how much putty was used. MEKP catalyst is needed for the putty to cure. It should be added around 1-2% based on the volume of the resin at temperatures around 77°F. Too much or too little MEKP catalyst will cause an improper cure. Cure time and pot life will vary depending on percentage of MEKP added and the temperature of the room. If 1% MEKP is added, there will be a longer pot life and it will cure slower than if 1.5% or 2% MEKP is added. Same goes for temperature. Lower temperatures result in slower pot life/cure time than if working in higher temperatures.

-Apply the putty to surface using a spreader or putty knife

-To get a hard tack free finish, follow up with PVA, a waxed gel coat or an Air Dry Coating.

-Uncured polyester resin can be removed from tools and equipment with acetone.

-Once fully cured, part can be sanded.

Available Sizes:

Quart, Gallon, call for additional sizes

Handling and Storage:

Closed containers should be stored in a cool, dry place. It should be stored at temperatures below 75°F and away from sunlight and heat sources. If stored properly, putty should stay good for 6 months.